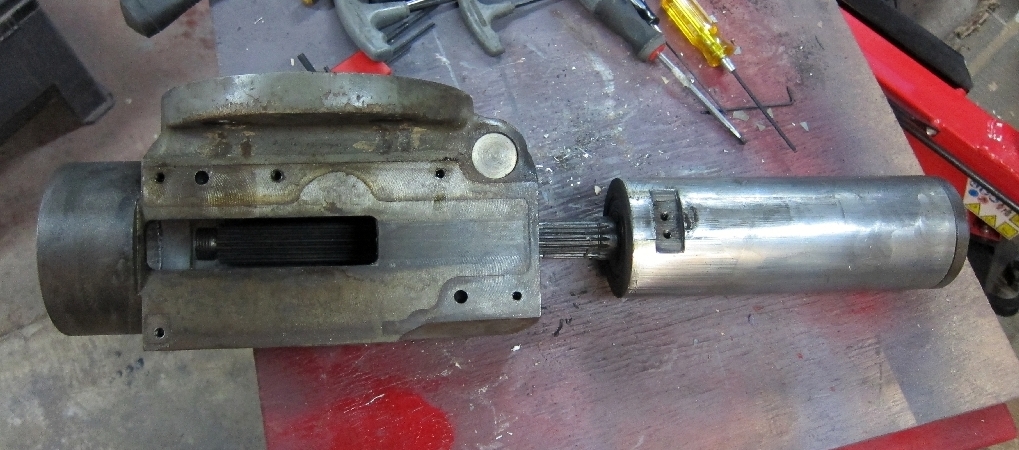

Ok, lets get the spindle out of the quill. The big "to do" on this end is taking the quill nut off. It is reverse threaded. I didn't have a pin wrench that would fit so I converted some ugly thing I had laying around. The nut is actually pretty easy to get off. Just smack the wrench a couple times. Did I mention it is reverse threaded ?

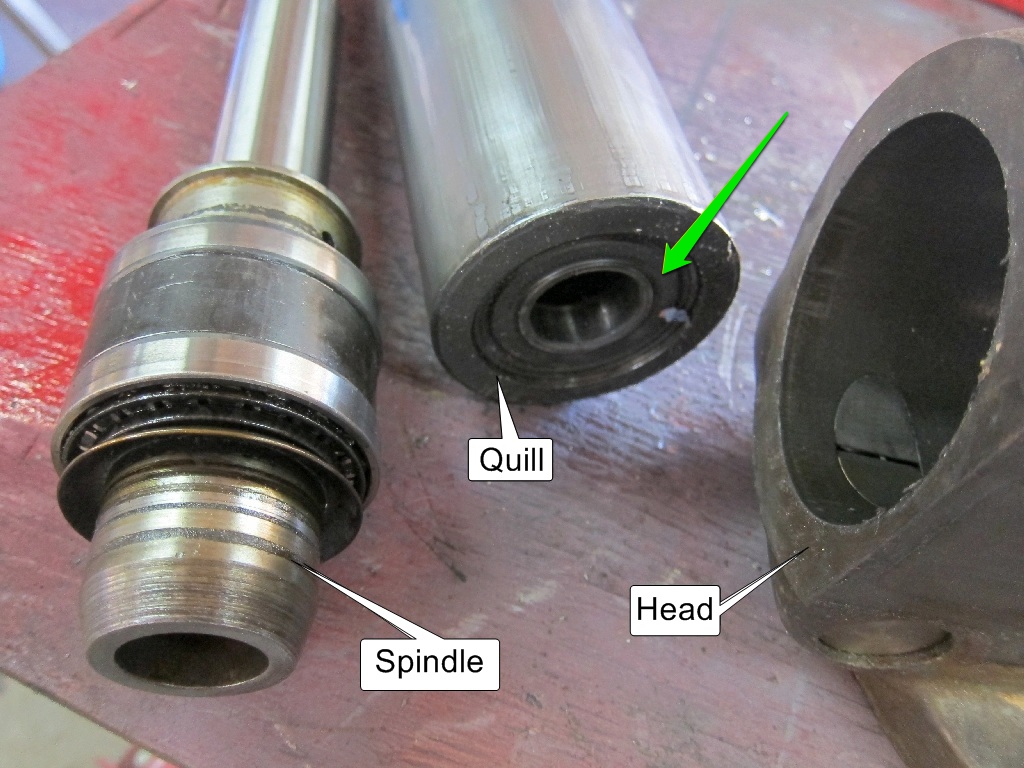

On the splined end, we have a snap ring. After you remove this, you will be able to tap the spindle out of the quill. While it was accessable, I changed the bearing on the end of the quill.

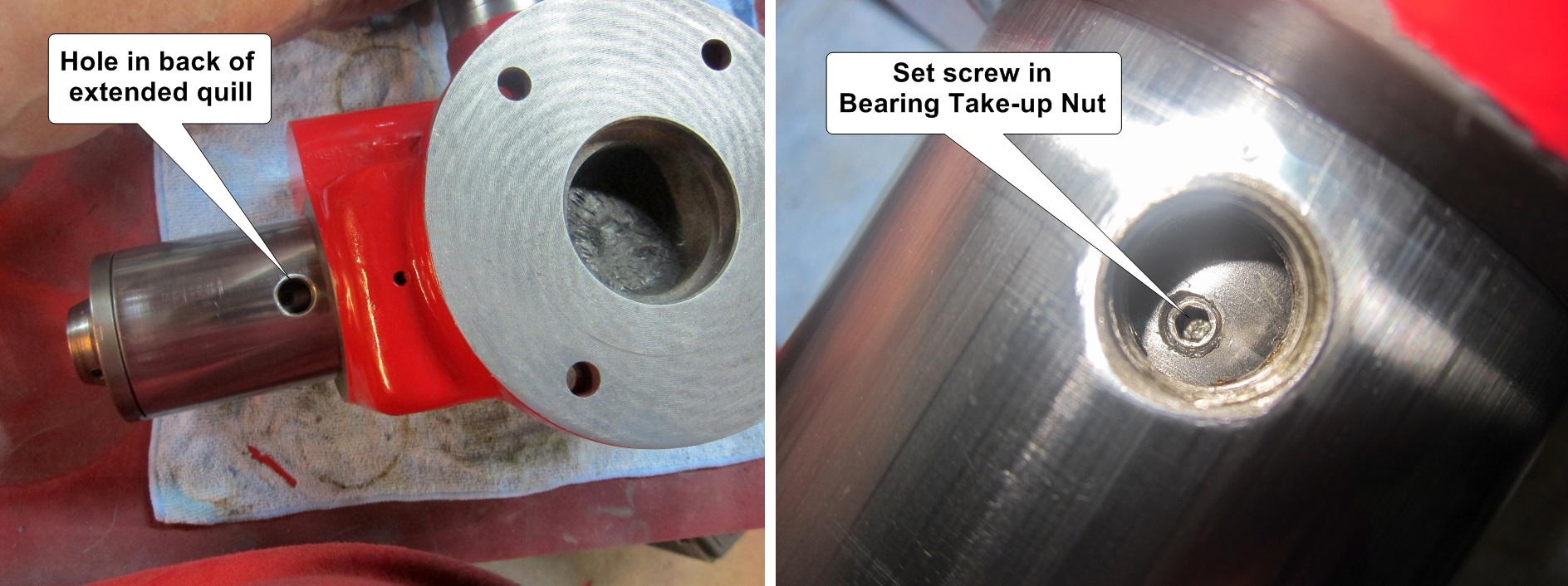

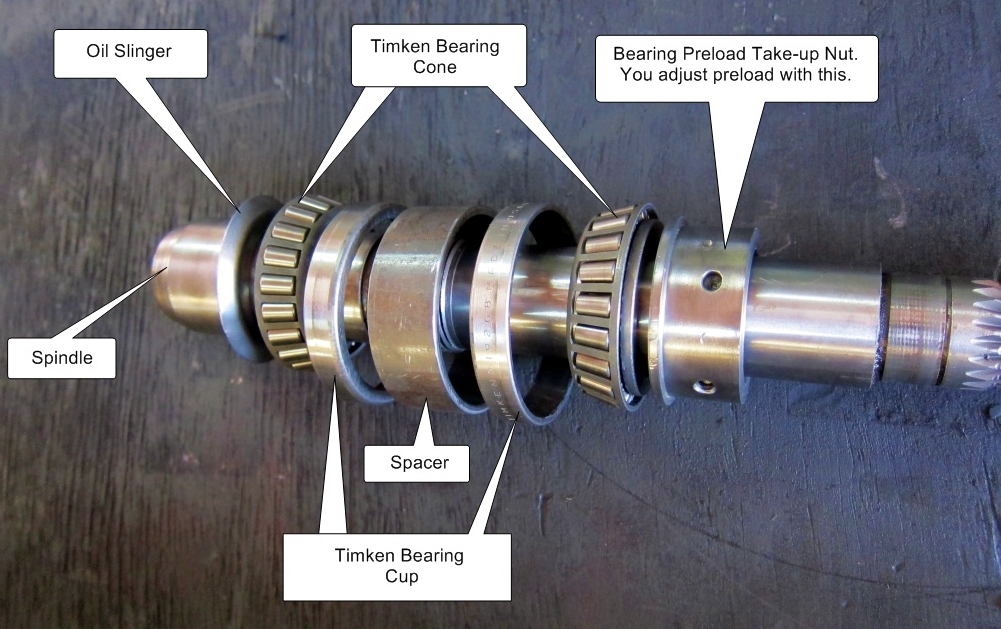

Time to disassemble the Spindle. The part with the holes around it is the Bearing Takeup Nut. One of those holes is actually a set screw that locks the nut. The other holes are for a pin wrench ( that I didn't have ). I just grabed the nut with a big wrench and unscrewed it. This nut is how the preload on the bearing is set. You can access it while the machine is all together by a hole in the back of the spindle. (small blow-up pic) If you remove this nut the bearing will come apart.

Soaking the bearings in some solvent. To get all the crud out.

All cleaned up, put back together and labeled.

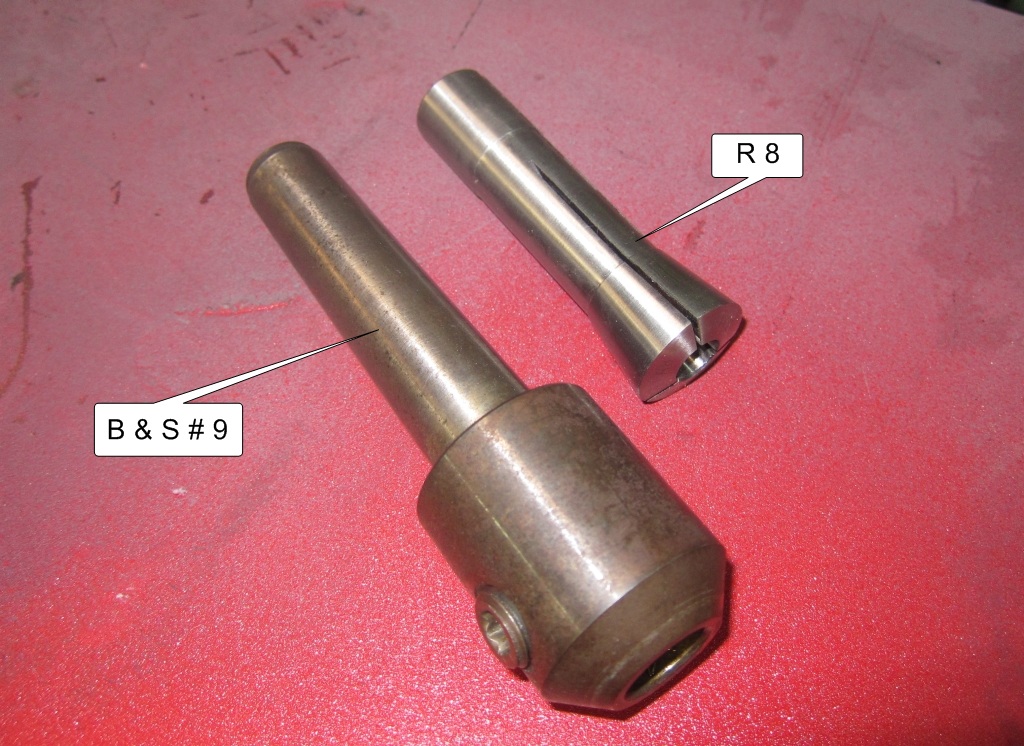

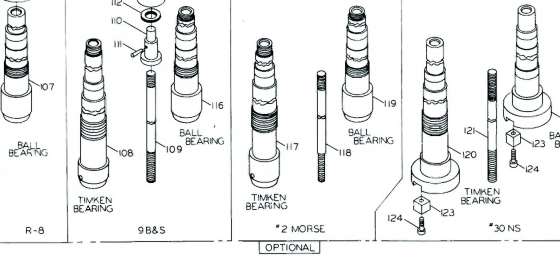

Looking back at the exploded head diagram we see that there were many different spindles available. Offering ball or Timken bearings. And 4 different tool holder tapers. This millrite was a B&S #9 with Timken bearings. The B&S #9 is a hardy standard but the tooling is hard to find and has a history of sticking in the spindle. I really wanted R8 which is by far the most popular. (For this machine)

Here is an R8 collet and a B&S #9 endmill holder. You can see that the end that is pushed up into the spindle (the taper) is very different. There is a company by the name of Wells Index that will regrind your spindle to take the R8. It runs about $300 (Aug 2013) to have it done. I decided to do just that.

Index Wells grinds the spindle, while it is in the quill for accuracy reasons. So I put everything back together and went to Home Depot and bought a piece of heavy duty sewer pipe and some caps that fit in the ends. Padded with bubble wrap and I had a package I could mail.

About a month later it came back looking like it had traveled around the world.

Looking down the end of the spindle you can see where they ground it. Now I have an R8 spindle with Timken bearings.