One of the scrap yards near me has about a zillion of these 5ft steel channels. They charge me about 10 bucks a piece. They are actually quite heavy and great for projects like this.

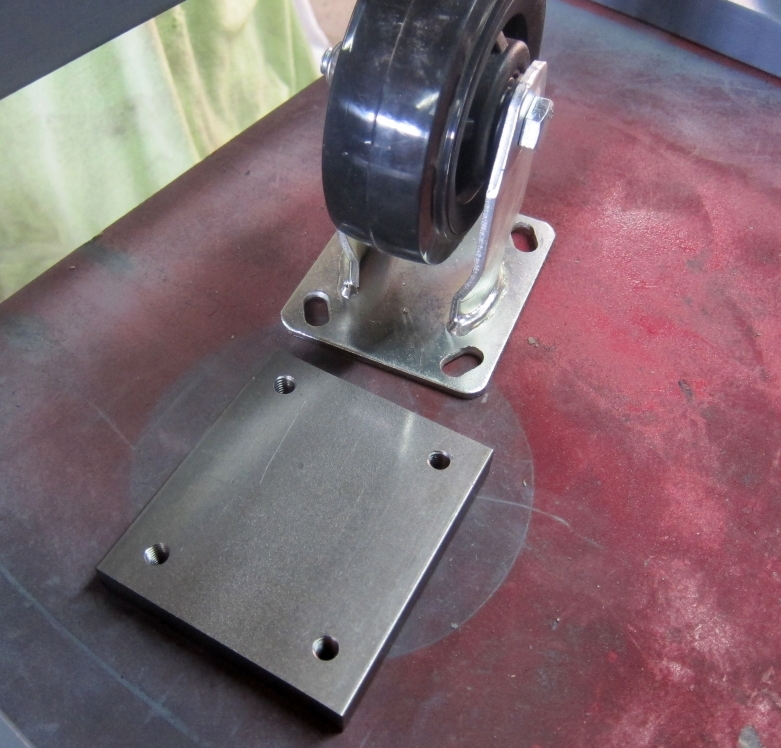

2 swivel casters, 2 fixed. and four thick chunks of steel to mount them on.

I thought it would look nicer if I welded little pieces of steel on the ends of the channel.

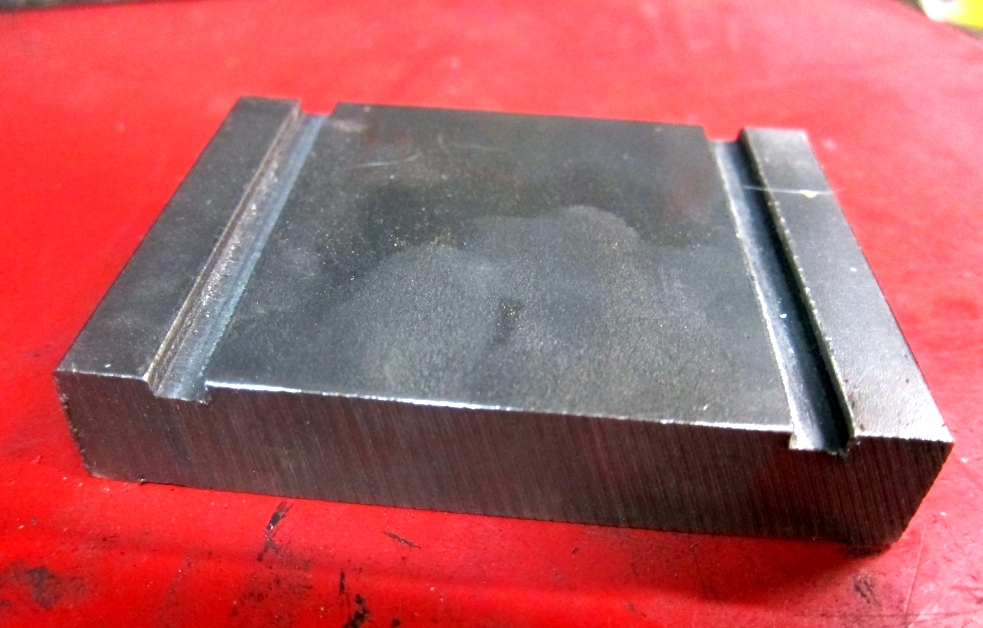

Here is the basic layout. I have this nasty habit of sketching out when it comes to positioning things like the casters plates. i decided to mill two slots into the plates so I didn't have to play with positioning. They locked right into place as far as alignment goes.

Clamped the plates into position and mig weld it up.

The bolts I used to clamp the dolly to the mill came with the mill. These may be common but I have never seen them. They are hollow and threaded on the insided. This allows you to bolt the dolly to the mill and run standoff leveling bolts down the inside of them.

Here we are all bolted up. If you click on the insert in the first picture, you can see a closeup of the hollow threaded bolts. The dolly rolls really easy. I am happy with the results. The second picture is just another view.

All painted up and ready for the casters